Bespoke Conformance Calibration Test Cards for Real-Time Label Inspection

Perceptor Inspection Technologies were pleased to be interviewed by Applied Image for their series of Valued Partner case studies.

We tell the story of how demand for a reliable, efficient and effective label verification solution lead to the creation of a bespoke Conformance Calibration Test Card for Perceptor IoT by the industry-leading Applied Image team.

The following excerpts are reproduced by kind permission of Applied Image.

The need for Real-Time Label Inspection & Verification

Even before Perceptor set out to develop their breakthrough product, manufacturers were already clamoring for reliable, efficient, and effective inspection solutions. The real-time label inspection and verification industry, essential for ensuring quality and compliance in various sectors like pharmaceuticals, food and beverage, and consumer goods, faces several critical challenges related to:

-

Accuracy and precision. This includes correctly identifying text, graphics, barcodes, and other relevant details. Any error in label inspection can lead to severe consequences, especially in highly regulated industries like pharmaceuticals.

-

Speed and efficiency in high-volume manufacturing environments where thousands of products are labeled per hour. Maintaining high accuracy at such speeds is a significant challenge.

-

Product and packaging variability that adds complexity. Different label shapes, sizes, and colors require adaptable and sophisticated inspection systems.

-

Regulatory compliance with constantly evolving standards across different regions and industries. Failure to comply can lead to legal issues, fines, and recalls.

-

Integrating label inspection systems with existing production processes, printers, and IT infrastructure without disrupting ongoing operations or adding excessive costs.

-

Minimizing false rejects and false accepts, which is crucial for operational efficiency and cost-effectiveness.

-

Environmental factors like lighting, vibration, dust, and temperature that can affect the performance of label inspection systems.

-

Managing inspection data and ensuring traceability for quality control and regulatory purposes.

-

Maintenance and timely upgrades that are required to keep the systems effective and updated.

-

Ensuring inspection system security and the privacy of sensitive data, especially with the rise of IoT and connected devices.

The bespoke Conformance Calibration Standard Test Card component, supplied by Applied Image, is integral to keeping Perceptor Inspection Technologies clients’ systems and processes going and ensuring they receive accurate information. This is crucial as the company’s end-users are in heavily regulated industries like healthcare, medical devices, and defense. The regulatory requirements are a powerful guardrail helping to ensure no product goes out with an inaccurate or duplicate label. If that happens, manufacturers can be subject to hefty fines. So, avoiding those penalties is a strong incentive to pursue flawless labeling. Achieving that degree of accuracy relies on the availability of a calibration card with exceptional precision, as supplied by Applied Image. Perceptor’s customers can utilize this calibration card and be confident that their equipment is functioning properly.

Meeting technical and regulatory standards

It was essential for Perceptor to bring its proprietary label inspection and verification solution to market with all its additional technical benefits and meet the ISO standards – 15426 for the hardware implementation and 15415 (2D) and 15416 (1D) code reading. ISO 15426 requires the image acquisition device to be calibrated every 90 days. Doing that requires a test card with known white and grayscale values to calibrate the camera sensor. The design team struggled to find a vendor that would supply the verification algorithm/DLL without the hardware and their own costlier solution.

Fortunately, Perceptor’s CEO, Mark Worlidge, was familiar with Applied Image as their test calibration cards were used at several of his previous companies. The unmatched precision that Applied Image is known for made it the only choice for test cards for image quality assessment in Perceptor's premium IoT product. Applied Image was also the only supplier that met Perceptor’s specialized requirements for a component compatible with the Zebra ZT610 (and soon the ZT620) printers.

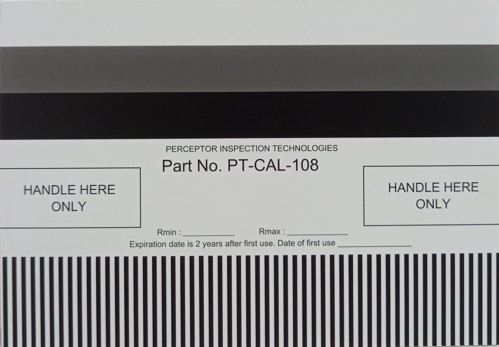

The Perceptor IoT Calibration Test card

Every Perceptor IoT kit for the Zebra ZT610 comes with a Calibration Test card, which includes Ronchi ruling bars and greyscale reflectants. Each card is manufactured to very precise tolerances and then measured so that the measured parameter values of the test card can be compared to those of Perceptor IoT.

The Applied Image calibration test card serves as a primary reference standard, with a traceability chain to national standards for all verifiers calibrated.

Mark Worlidge, CEO of Perceptor Inspection Technologies, explained, “Our team was pleased with the quality and precision of the part we received from Applied Image. Applied Image's ability to simplify complex concepts and provide clear steps toward accuracy through the design phase was extremely helpful. Calibrating Perceptor IoT with an Applied Image conformance test card ensures Perceptor IoT accurately and repeatedly inspects labels with consistency and accuracy. The collaboration between the Perceptor developers and the Applied Image team brought our vision to life, resulting in a perfectly aligned test card that will work seamlessly in any vertical industry sector.”